What are basketballs made of? What materials go into the manufacturing process? How has this changed over time? In this article, we will answer all of these questions and provide a comprehensive overview of the history of basketball ball construction.

The raw materials used to make basketballs today

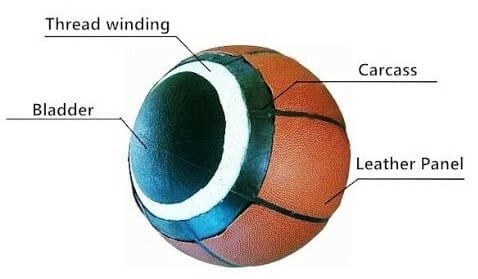

The exterior covers on a basketball are either original leather, synthetic rubber, or composite leather. The inside contains an internal bladder and also the rest of the carcass. The bladder is made from styrene while carcasses are nylon or polyester.

How have basketballs been made over the years?

Leather has been used to make the cover of leather balls for a long time. The first basketballs were made in a spherical shape from pure leather and continued to be used until the early 1960s when synthetic materials began to be introduced. The same material is still used in some vintage indoor balls today but most basketballs are synthetic now.

The benefits of using different materials in basketballs’ construction

There are some benefits to using leather for basketballs as opposed to other materials. It is durable and can withstand a lot of wear and tear. It is also flexible, which allows the basketball to bounce properly. Leather also has a good grip so that players can control it easily.

However, leather has some drawbacks as well. It is not water-resistant and can become heavy when wet. Additionally, it is expensive to produce and requires a lot of care and maintenance. For this reason, rubber basketballs or synthetic balls that try to imitate leather have been introduced and nowadays account for the majority of produced basketballs today.

Are there any potential environmental concerns with some of the materials used in basketball manufacturing today?

One potential environmental concern with the use of synthetic materials for basketballs is that they are not biodegradable. This means that once they are disposed of, they will remain in the environment for a long time. Additionally, some synthetic materials can release harmful toxins when they are burned. For some people, it is important to consider these potential impacts when deciding whether or not to use a certain type of basketball.

Leather basketballs on the other side do not pose such concerns, however, they involve the use of materials produced from animals, which some people may not agree with. Farming animals and using them for producing leather is not compliant with their values.

Furthermore, basketballs are often shipped in large containers across oceans and countries, which has environmental consequences. The shipping of goods by air or sea is known to create a lot of emissions that contribute to climate change. What can we do as consumers? We should consider buying products locally manufactured instead of imported ones when possible to reduce emissions but again this is not possible most of the time in today’s globalized economy.

The process of making a typical basketball

The Ball’s Cover

Basketball covers come in various kinds. High-quality leather balls meant to be used in indoor courts can be made of quality processed leather covers. Outdoor balls are made from different materials including synthetic rubber or composites. The materials are sliced into six or more separate panels that are then wrapped around the ball. Before placing a piece onto a ball, however, the stamps or embossments are fitted or printed on them. When a leather panel is made the piece is then stitched together. A synthetic rubber ball is made of composite rubber flat panels that have been glued together to hold them together. After sealing the sheets, the markings on the ball can be applied.

The inner bladder of the ball

Located inside a basketball is an internal bladder, usually made from black butyl rubber. The purpose of the interior bladder is to effectively retain air to keep the ball bouncing. The butyl rubber bladder consists of initially flat pieces that are then melted to form a ball. A small gap is made to the bladder, which allows for the insertion of the air filler tube. A valve is then adjusted into this hole, traveling through to the outer layer whose purpose is to hold air.

Shaping the Ball’s Insides

Compared to the bladder, the manufacturing of the remaining internal parts seems quite odd. Uniformly shaped basketballs should be made from polyester/nylon fiber threads that wrap around the bladder. It is through these threads that a cylindrical ball forms a spiral shape which prevents bending or dislocating it. Some balls have more quality threads which improve their performance. Street balls usually have polyester threads, professional balls have nylon threads.

Quality Control

During production processes, periodic inspections are performed so that finished basketballs can maintain air and correct surface imperfections. Machines like punch press, die vulcanizer, and printing equipment was carefully designed first to maximize the utilization of the material to produce perfect pieces. Assembly processes involve numerous steps done on the job, and assembly workers are trained in the detection of defects and rejecting nonsuitable materials. Quality testing involves checking the inner bladder and the air filler tube if it holds air for a long time when inflated. The basketball is put under adequate pressure for over 24 hours. They are also testing the bouncing height when the basketball is dropped from prespecified heights. A final inspection also incorporates weight-control testing for the carcasses and panels.

The future of basketball material design and production

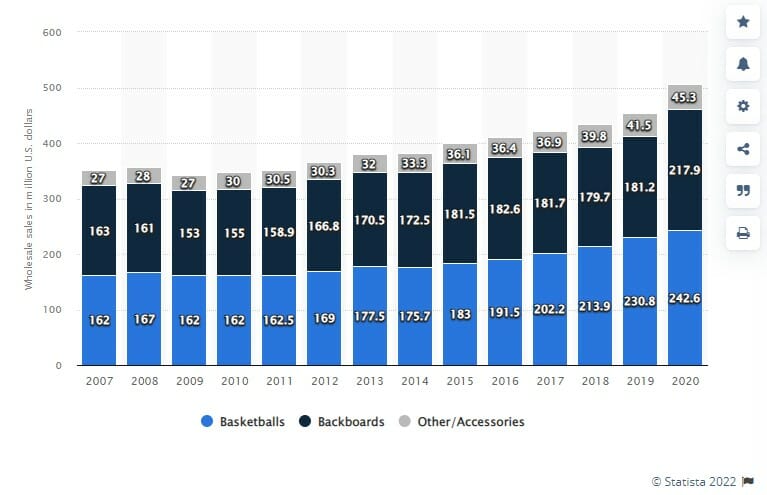

Basketball sales are increasing significantly in the last decades as the popularity of basketball has increased in the USA but also worldwide. Another aspect of the global popularity of basketball is its sharpening of collectors’ enthusiasm for souvenir ball collection themed in the colors of their favorite teams, made for specific events like the Basketball World Cup and autographed balls. According to research by Statista, basketball balls sales have increased from 166 million USD in 2007, to over 242 million USD in 2020 (which is an impressive 48% increase).

There is no question that demand will follow an increasing trend in the next years, as the game breaks into virgin markets such as China, India and Indonesia the following years. With a huge number of basketballs that need to get into circulation, the question is what will be produced and how? What materials will be used to produce them and where? What are the most efficient production processes today that make it possible for millions of balls to enter the global market at affordable prices? It is obvious that nylon threads and polyester threads will be used as the basketball material of choice more and more as it has happened with other sports.

FAQs

Is the NBA ball leather?

The Wilson official NBA ball is made of genuine cow leather and designed to exceed the NBA standards of the highest quality for the game.

What are NBA balls filled with?

All Wilson official balls are inflated with air. The official NBA Basketball is an evolution of the original leather ball and features a composite leather cover for improved softness, durability, performance and grip. An official ball is inflated to a pressure of between 7.5 and 8.5 psi, according to the NBA’s rules. The NBA maintains fair gaming conditions by regulating a basketball’s air pressure.

How does the NBA ensure that all of its basketballs meet high quality material and safety standards?

The NBA has a rigorous quality control process that each ball must pass to be used in an official game. This includes testing for weight, size, shape, bounce and air pressure.

What is inside of a basketball?

The inner bladder of the basketball has a spherical shape and is made from black butyl rubber. The purpose of the internal bladder is to effectively retain air to keep the basketball bouncing.

What animal is a basketball made of?

The outer layer of an animal-made basketball is made of leather originating from a cow. The supplier of the leather for the official NBA ball is Horween Leather Company, a company that is using 100% cowhide for the balls. However most balls are not animal-made but made from polyester thread.

Are basketballs vegan?

No, official NBA basketballs are not vegan as they contain materials from animals. The butyl rubber inner bladder is not derived from any animal products, however, the cover of the indoor balls is made of leather, as cowhide and horsehide can be used in the production process. However, most of the outdoor balls that you are using in outdoor courts are 100% synthetic as they consist of a nylon thread outside and a polyethylene bag inside, making them vegan.

What does the NBA do with old basketballs materials?

The NBA reuses a lot of the old materials from basketballs. For example, they will take the interior bladder and use it to create new balls. They also recycle the leather coverings to be used in other products such as wallets or shoes.

Are leather balls or synthetic rubber balls better?

Leather basketballs are more expensive than rubber balls and also have a better grip. They are generally easier to shoot with and handle but can get slippery in wet conditions, so if you want to play outside all year long then go for a synthetic rubber ball that also retains air longer if it is left outside.

Conclusion

In this article we tried to answer all questions related to what are basketballs made of that you might have. The basketball industry is a multi-billion dollar business and it is only getting bigger. With the global population rising, more and more people are playing the game and hence the demand for balls of the material that they are made of is only getting higher. What this means for the industry is that there will be continuous innovation and improvement in the materials used to make basketballs.

- How to Pass a Basketball (5 effective tips) - August 25, 2022

- Learn How to Spin a Basketball on your Finger in less than 3 minutes - July 18, 2022

- Where are basketballs manufactured? (hint : mostly Asia) - June 10, 2022